Project 3.8: "Remote-Controlled Robot"

🚀 What you’ll learn

- ✅ Goal 1: Build a direct remote controller (R32 + Joystick) that commands a robot (R32 + motors) via IR.

- ✅ Goal 2: Implement robot status feedback (ACK and mode reports) for confident control.

- ✅ Goal 3: Add compensated delay to keep controls responsive without flooding signals.

- ✅ Goal 4: Create assisted automatic modes (Turbo, Quiet, Normal, Stop) with friendly toggles.

- ✅ Goal 5: Achieve precise position control using timed motor pulses and step counts.

Key ideas

- Direct control: Joystick buttons map to directions and modes; IR carries commands to the robot.

- Feedback: The robot replies with short acknowledgments over Bluetooth or prints clear serial logs.

- Compensation: Small adaptive delays and command spacing keep control snappy.

- Assistance: Modes reduce cognitive load — fast/quiet/stop at a tap.

- Precision: Time-based pulses emulate step control without encoders.

🧱 Blocks glossary (used in this project)

- Digital input (pull‑up): Reads joystick buttons A–F (pressed = 0).

- Analog input (ADC): Reads joystick X/Y values (0–4095), optionally for speed.

- IR send/receive: Transmit commands from controller to robot; decode on robot side.

- Digital output: Set motor direction pins (IN1–IN4).

- PWM output: Set motor speed (ENA/ENB duty).

- Bluetooth peripheral: Optional robot feedback “ACK: …” to a PC (useful in class demos).

- def function: Encapsulate reusable actions (send_cmd, apply_mode, pulse_move).

- Loop: Continuous control cycle with friendly timing and logs.

🧰 What you need

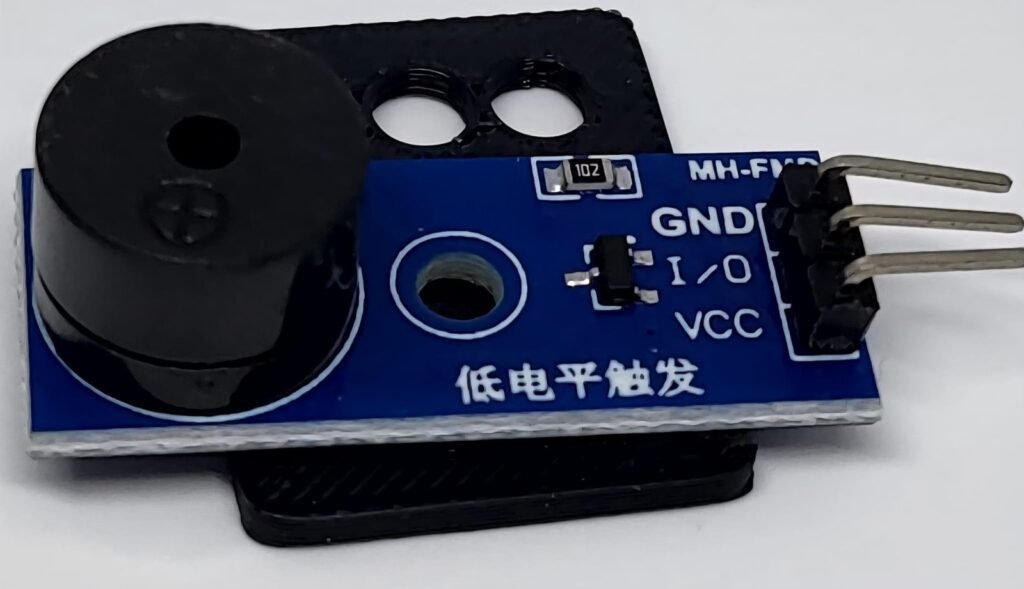

| Part | How many? | Pin connection (R32) |

|---|---|---|

| D1 R32 (Controller) | 1 | Joystick Shield buttons: A(26), B(25), C(17), D(16), E(27), F(14); IR TX → Pin 26 |

| D1 R32 (Robot) | 1 | IR RX → Pin 26; L298N: ENA → Pin 5 (PWM), ENB → Pin 18 (PWM), IN1 → 23, IN2 → 19, IN3 → 13, IN4 → 21 |

| TT Motors + L298N driver | 2 + 1 | Motors to L298N OUT1/OUT2 (left), OUT3/OUT4 (right) |

| Optional Bluetooth (robot) | 1 | Built-in (no pins), for “ACK” feedback to a PC |

- Share GND between controller R32, robot R32, and L298N.

- Aim the controller’s IR transmitter towards the robot’s IR receiver (20–50 cm clear line of sight).

✅ Before you start

- Connect both R32 boards via USB and open two serial monitors: “Controller” and “Robot”.

- Quick serial test:

print("Ready!") # Confirm serial is working

🎮 Microprojects (5 mini missions)

🎮 Microproject 3.8.1 – Direct remote control

Goal: Map joystick buttons A–D to robot directions: Forward, Backward, Left, Right (IR).

Controller code (A–D → IR):

# Microproject 3.8.1 – Controller: A–D buttons send IR direction commands

import machine # Load hardware pin library

import irremote # Load IR communication library

import time # Load time library for delays

# Prepare joystick button inputs (active LOW with pull-up)

pinA = machine.Pin(26, machine.Pin.IN, machine.Pin.PULL_UP) # Button A

pinB = machine.Pin(25, machine.Pin.IN, machine.Pin.PULL_UP) # Button B

pinC = machine.Pin(17, machine.Pin.IN, machine.Pin.PULL_UP) # Button C

pinD = machine.Pin(16, machine.Pin.IN, machine.Pin.PULL_UP) # Button D

# Prepare IR transmitter on Pin 26 (power 100%, not inverted)

ir_tx = irremote.NEC_TX(26, False, 100) # IR TX setup

print("[Controller] IR TX ready on 26") # Serial: IR init

# Canonical direction codes

CODE_FORWARD = 0x18 # Forward

CODE_BACKWARD = 0x52 # Backward

CODE_LEFT = 0x08 # Left

CODE_RIGHT = 0x5A # Right

def send_cmd(code): # Helper: send IR command

ir_tx.transmit(0x00, code, 0x00) # Send code (addr=0x00, ctrl=0x00)

print("[Controller] CMD:", hex(code)) # Serial: log send

while True: # Main control loop

if pinA.value() == 0: # If A pressed (LOW)

send_cmd(CODE_FORWARD) # Send forward

time.sleep_ms(250) # Debounce spacing

if pinB.value() == 0: # If B pressed (LOW)

send_cmd(CODE_BACKWARD) # Send backward

time.sleep_ms(250) # Debounce spacing

if pinC.value() == 0: # If C pressed (LOW)

send_cmd(CODE_LEFT) # Send left

time.sleep_ms(250) # Debounce spacing

if pinD.value() == 0: # If D pressed (LOW)

send_cmd(CODE_RIGHT) # Send right

time.sleep_ms(250) # Debounce spacing

Robot code (decode A–D):

# Microproject 3.8.1 – Robot: Decode IR directions and drive motors

import irremote # Load IR communication library

import machine # Load hardware pin/PWM library

import time # Load time library

# Prepare IR receiver on Pin 26 with buffer size 8

ir_rx = irremote.NEC_RX(26, 8) # IR RX setup

print("[Robot] IR RX ready on 26") # Serial: IR init

# Prepare motor direction pins (L298N)

in1 = machine.Pin(23, machine.Pin.OUT) # IN1 left

in2 = machine.Pin(19, machine.Pin.OUT) # IN2 left

in3 = machine.Pin(13, machine.Pin.OUT) # IN3 right

in4 = machine.Pin(21, machine.Pin.OUT) # IN4 right

print("[Robot] Direction pins set 23,19,13,21") # Serial: pins ready

# Prepare PWM speed pins

pwmA = machine.PWM(machine.Pin(5)) # ENA left PWM

pwmB = machine.PWM(machine.Pin(18)) # ENB right PWM

pwmA.freq(2000) # Set PWM frequency 2kHz

pwmB.freq(2000) # Set PWM frequency 2kHz

speed = 650 # Default medium speed

pwmA.duty(speed) # Apply left duty

pwmB.duty(speed) # Apply right duty

print("[Robot] Speed duty =", speed) # Serial: speed init

# Canonical direction codes (must match controller)

CODE_FORWARD = 0x18 # Forward

CODE_BACKWARD = 0x52 # Backward

CODE_LEFT = 0x08 # Left

CODE_RIGHT = 0x5A # Right

def stop_all(): # Helper: stop motors (coast)

in1.value(0) # Left IN1 OFF

in2.value(0) # Left IN2 OFF

in3.value(0) # Right IN3 OFF

in4.value(0) # Right IN4 OFF

print("[Robot] STOP") # Serial: stopped

def drive_forward(): # Helper: forward direction

in1.value(1) # Left forward ON

in2.value(0) # Left backward OFF

in3.value(1) # Right forward ON

in4.value(0) # Right backward OFF

print("[Robot] FORWARD") # Serial: forward

def drive_backward(): # Helper: backward direction

in1.value(0) # Left forward OFF

in2.value(1) # Left backward ON

in3.value(0) # Right forward OFF

in4.value(1) # Right backward ON

print("[Robot] BACKWARD") # Serial: backward

def turn_left(): # Helper: spin left

in1.value(0) # Left forward OFF

in2.value(1) # Left backward ON

in3.value(1) # Right forward ON

in4.value(0) # Right backward OFF

print("[Robot] LEFT") # Serial: left turn

def turn_right(): # Helper: spin right

in1.value(1) # Left forward ON

in2.value(0) # Left backward OFF

in3.value(0) # Right forward OFF

in4.value(1) # Right backward ON

print("[Robot] RIGHT") # Serial: right turn

while True: # Main decode loop

if ir_rx.any(): # If any IR code arrived

code = ir_rx.code[0] # Read first buffered code

print("[Robot] IR:", hex(code)) # Serial: show code

if code == CODE_FORWARD: # If forward

drive_forward() # Drive forward

elif code == CODE_BACKWARD: # If backward

drive_backward() # Drive backward

elif code == CODE_LEFT: # If left

turn_left() # Spin left

elif code == CODE_RIGHT: # If right

turn_right() # Spin right

else: # Otherwise unknown

stop_all() # Stop safely

else: # If no IR this cycle

# Optional idle behavior: keep last state or stop

pass # Do nothing to maintain current motion

time.sleep_ms(150) # Short loop delay for responsiveness

Reflection: You’ve built the basic “remote → robot” pipeline.

Challenge: Add STOP on button F (controller) and decode it on robot.

🎮 Microproject 3.8.2 – Robot status feedback

Goal: Robot sends “ACK” status back (Bluetooth to PC) and prints concise serial logs on actions.

Robot feedback code (optional BLE):

# Microproject 3.8.2 – Robot: Bluetooth ACK feedback for actions

import ble_peripheral # Load Bluetooth peripheral helper

import ble_handle # Load Bluetooth callback handle

# Create Bluetooth peripheral named 'Robot-R32'

ble_p = ble_peripheral.BLESimplePeripheral('Robot-R32') # BLE peripheral

handle = ble_handle.Handle() # BLE handle

print("[Robot] BLE 'Robot-R32' ready") # Serial: BLE init

def ack(label): # Helper: send ACK feedback

ble_p.send("ACK:" + str(label)) # Send acknowledgment string

print("[Robot] ACK:", label) # Serial: log ACK

How to use: call ack("FORWARD"), ack("LEFT"), or ack("MODE:TURBO") after executing actions in the robot code.

Reflection: ACK builds trust — students see actions confirmed.

Challenge: Add error feedback “ERR:UNKNOWN” for unknown IR codes.

🎮 Microproject 3.8.3 – Compensated delay control

Goal: Controller spaces commands adaptively to avoid flooding and keep responsive control.

Controller code (adaptive spacing):

# Microproject 3.8.3 – Controller: adaptive spacing for IR commands

import machine # Load hardware pin library

import irremote # Load IR communication library

import time # Load time library

# Inputs (A–D directions, F stop)

pinA = machine.Pin(26, machine.Pin.IN, machine.Pin.PULL_UP) # A

pinB = machine.Pin(25, machine.Pin.IN, machine.Pin.PULL_UP) # B

pinC = machine.Pin(17, machine.Pin.IN, machine.Pin.PULL_UP) # C

pinD = machine.Pin(16, machine.Pin.IN, machine.Pin.PULL_UP) # D

pinF = machine.Pin(14, machine.Pin.IN, machine.Pin.PULL_UP) # F

# IR TX

ir_tx = irremote.NEC_TX(26, False, 100) # IR transmitter

print("[Controller] IR TX adaptive") # Serial: init

# Codes

CODE_FORWARD = 0x18 # Forward

CODE_BACKWARD = 0x52 # Backward

CODE_LEFT = 0x08 # Left

CODE_RIGHT = 0x5A # Right

CODE_STOP = 0x19 # Stop

# Adaptive timing state

last_send_ms = 0 # Last send timestamp (ms)

base_gap_ms = 200 # Minimum gap between sends

extra_gap_ms = 0 # Additional gap (adaptive)

def now_ms(): # Helper: current ms

return time.ticks_ms() # Return ticks in ms

def can_send(): # Helper: check spacing

elapsed = time.ticks_diff(now_ms(), last_send_ms) # Compute ms since last send

return elapsed >= (base_gap_ms + extra_gap_ms) # Compare with adaptive gap

def sent(): # Helper: mark a send

global last_send_ms # Use global timestamp

last_send_ms = now_ms() # Update last send time

def bump_gap(): # Helper: increase adaptive gap

global extra_gap_ms # Use global gap

extra_gap_ms = min(extra_gap_ms + 50, 300) # Increase up to 300 ms

def reduce_gap(): # Helper: reduce adaptive gap

global extra_gap_ms # Use global gap

extra_gap_ms = max(extra_gap_ms - 20, 0) # Reduce down to 0 ms

def send_cmd(code): # Helper: transmit IR command

ir_tx.transmit(0x00, code, 0x00) # Send code

print("[Controller] CMD:", hex(code), # Serial: log cmd and gap

"| gap", base_gap_ms + extra_gap_ms, "ms")

sent() # Mark send

reduce_gap() # Slightly reduce gap on successful send

while True: # Control loop

if pinA.value() == 0 and can_send(): # If A pressed and spacing ok

send_cmd(CODE_FORWARD) # Send forward

if pinB.value() == 0 and can_send(): # If B pressed and spacing ok

send_cmd(CODE_BACKWARD) # Send backward

if pinC.value() == 0 and can_send(): # If C pressed and spacing ok

send_cmd(CODE_LEFT) # Send left

if pinD.value() == 0 and can_send(): # If D pressed and spacing ok

send_cmd(CODE_RIGHT) # Send right

if pinF.value() == 0 and can_send(): # If F pressed and spacing ok

send_cmd(CODE_STOP) # Send stop

bump_gap() # Increase adaptive gap after STOP

time.sleep_ms(40) # Short polling delay

Reflection: Adaptive spacing balances responsiveness with reliability.

Challenge: Show current gap on an LCD (Project 3.3) or on serial once per second.

🎮 Microproject 3.8.4 – Assisted automatic modes

Goal: E toggles speed modes (Turbo, Quiet, Normal, Stop), robot applies PWM.

Controller code (mode sends):

# Microproject 3.8.4 – Controller: E toggles assisted modes via IR

import machine # Load hardware pin library

import irremote # Load IR library

import time # Load time library

pinE = machine.Pin(27, machine.Pin.IN, machine.Pin.PULL_UP) # Button E (mode toggle)

ir_tx = irremote.NEC_TX(26, False, 100) # IR transmitter

print("[Controller] Mode toggle ready") # Serial: init

MODE_TURBO = 0x55 # Turbo mode code

MODE_QUIET = 0x16 # Quiet mode code

MODE_NORMAL = 0x46 # Normal mode code

MODE_STOP = 0x19 # Stop mode code

modes = [MODE_NORMAL, MODE_TURBO, MODE_QUIET, MODE_STOP] # Mode cycle

idx = 0 # Current mode index

def send_mode(code): # Helper: send IR mode

ir_tx.transmit(0x00, code, 0x00) # Send mode code

print("[Controller] MODE:", hex(code)) # Serial: log mode

while True: # Toggle loop

if pinE.value() == 0: # If E pressed

idx = (idx + 1) % len(modes) # Advance mode index

send_mode(modes[idx]) # Send new mode

time.sleep_ms(300) # Debounce delay

time.sleep_ms(40) # Short loop sleep

Robot code (apply modes):

# Microproject 3.8.4 – Robot: apply PWM speed modes

import irremote # Load IR library

import machine # Load hardware PWM/pin library

import time # Load time library

ir_rx = irremote.NEC_RX(26, 8) # IR receiver

pwmA = machine.PWM(machine.Pin(5)) # Left PWM

pwmB = machine.PWM(machine.Pin(18)) # Right PWM

pwmA.freq(2000) # PWM frequency 2kHz

pwmB.freq(2000) # PWM frequency 2kHz

MODE_TURBO = 0x55 # Turbo code

MODE_QUIET = 0x16 # Quiet code

MODE_NORMAL = 0x46 # Normal code

MODE_STOP = 0x19 # Stop code

speed = 650 # Default duty

pwmA.duty(speed) # Apply left duty

pwmB.duty(speed) # Apply right duty

print("[Robot] Start duty =", speed) # Serial: speed init

def apply_speed(duty): # Helper: set both PWMs

global speed # Use global speed var

speed = duty # Update stored speed

pwmA.duty(speed) # Apply left duty

pwmB.duty(speed) # Apply right duty

print("[Robot] Duty =", speed) # Serial: log applied duty

def emergency_stop(): # Helper: set duty to 0

pwmA.duty(0) # Left duty 0

pwmB.duty(0) # Right duty 0

print("[Robot] STOP duty=0") # Serial: stop

while True: # Mode loop

if ir_rx.any(): # If any IR code available

code = ir_rx.code[0] # Read first buffered code

print("[Robot] IR MODE:", hex(code)) # Serial: show mode code

if code == MODE_TURBO: # If turbo

apply_speed(1023) # Max duty

elif code == MODE_QUIET: # If quiet

apply_speed(400) # Low duty

elif code == MODE_NORMAL: # If normal

apply_speed(650) # Medium duty

elif code == MODE_STOP: # If stop

emergency_stop() # Stop motors

time.sleep_ms(150) # Short loop delay

Reflection: Assisted modes simplify speed control to a single button.

Challenge: Display current mode via Bluetooth ACK from the robot (Microproject 3.8.2).

🎮 Microproject 3.8.5 – Precise position control

Goal: Use timed pulses to move a fixed “step” distance; accumulate steps for precision.

Robot code (timed pulses):

# Microproject 3.8.5 – Robot: precise position via timed pulses (no encoders)

import irremote # Load IR library

import machine # Load hardware pin/PWM library

import time # Load time library

# IR RX

ir_rx = irremote.NEC_RX(26, 8) # IR receiver

print("[Robot] Precision pulse ready") # Serial: init

# Motor pins

in1 = machine.Pin(23, machine.Pin.OUT) # IN1 left

in2 = machine.Pin(19, machine.Pin.OUT) # IN2 left

in3 = machine.Pin(13, machine.Pin.OUT) # IN3 right

in4 = machine.Pin(21, machine.Pin.OUT) # IN4 right

# PWM pins

pwmA = machine.PWM(machine.Pin(5)) # ENA left

pwmB = machine.PWM(machine.Pin(18)) # ENB right

pwmA.freq(2000) # PWM frequency

pwmB.freq(2000) # PWM frequency

pwmA.duty(700) # Duty for pulses

pwmB.duty(700) # Duty for pulses

# Codes for pulse control (reuse direction codes for stepping)

CODE_STEP_FWD = 0x18 # Step forward

CODE_STEP_BACK = 0x52 # Step backward

STEP_MS = 200 # Pulse duration per step (ms)

steps_count = 0 # Accumulated step counter

def pulse_forward(ms): # Helper: one forward pulse

in1.value(1) # Left forward ON

in2.value(0) # Left backward OFF

in3.value(1) # Right forward ON

in4.value(0) # Right backward OFF

time.sleep_ms(ms) # Hold forward for ms

in1.value(0) # Left forward OFF

in3.value(0) # Right forward OFF

print("[Robot] Pulse FWD", ms, "ms") # Serial: log pulse

def pulse_backward(ms): # Helper: one backward pulse

in1.value(0) # Left forward OFF

in2.value(1) # Left backward ON

in3.value(0) # Right forward OFF

in4.value(1) # Right backward ON

time.sleep_ms(ms) # Hold backward for ms

in2.value(0) # Left backward OFF

in4.value(0) # Right backward OFF

print("[Robot] Pulse BACK", ms, "ms") # Serial: log pulse

while True: # Precision control loop

if ir_rx.any(): # If any IR code available

code = ir_rx.code[0] # Read first code

print("[Robot] IR STEP:", hex(code)) # Serial: show step code

if code == CODE_STEP_FWD: # If forward step

pulse_forward(STEP_MS) # Execute pulse

steps_count = steps_count + 1 # Increment step counter

print("[Robot] Steps =", steps_count) # Serial: log steps

elif code == CODE_STEP_BACK: # If backward step

pulse_backward(STEP_MS) # Execute pulse

steps_count = steps_count - 1 # Decrement step counter

print("[Robot] Steps =", steps_count) # Serial: log steps

time.sleep_ms(120) # Short loop delay

Reflection: Timed pulses let you “step” the robot forward/backward predictably.

Challenge: Add left/right stepping with smaller pulse time (STEP_MS = 150).

✨ Main project – Remote-controlled robot with feedback, compensation, modes, and precision

🔧 Blocks steps (with glossary)

- Digital input + IR send (controller): Map joystick buttons A–F to direction, stop, and mode codes.

- IR receive + motor control (robot): Decode and drive motors (IN1–IN4 + ENA/ENB).

- Bluetooth ACK (robot): Optionally send “ACK:CMD/MODE” to a PC for status feedback.

- Compensated delay (controller): Adaptive spacing between IR sends to avoid flooding.

- Precise pulses (robot): Use timed movement pulses to emulate position steps.

🐍 MicroPython code (complete system)

# Project 3.8 – Remote-Controlled Robot (Controller + Robot)

# Controller: Joystick buttons → IR commands/modes with adaptive spacing.

# Robot: IR decode → Motor control + optional Bluetooth ACK + pulse precision.

# ---------- CONTROLLER (R32 #1) ----------

import machine # Load hardware pin library

import irremote # Load IR communication library

import time # Load time library

# Buttons A–F (active LOW)

pinA = machine.Pin(26, machine.Pin.IN, machine.Pin.PULL_UP) # A forward

pinB = machine.Pin(25, machine.Pin.IN, machine.Pin.PULL_UP) # B backward

pinC = machine.Pin(17, machine.Pin.IN, machine.Pin.PULL_UP) # C left

pinD = machine.Pin(16, machine.Pin.IN, machine.Pin.PULL_UP) # D right

pinE = machine.Pin(27, machine.Pin.IN, machine.Pin.PULL_UP) # E mode cycle

pinF = machine.Pin(14, machine.Pin.IN, machine.Pin.PULL_UP) # F stop / step

# IR TX setup

ir_tx = irremote.NEC_TX(26, False, 100) # IR transmitter

print("[Controller] IR TX ready") # Serial: IR init

# Direction/step codes

CODE_FORWARD = 0x18 # Forward

CODE_BACKWARD = 0x52 # Backward

CODE_LEFT = 0x08 # Left

CODE_RIGHT = 0x5A # Right

CODE_STOP = 0x19 # Stop

# Mode codes

MODE_TURBO = 0x55 # Turbo

MODE_QUIET = 0x16 # Quiet

MODE_NORMAL = 0x46 # Normal

# Adaptive timing state

last_send_ms = 0 # Last send time

base_gap_ms = 200 # Base min gap

extra_gap_ms = 0 # Adaptive extra gap

# Mode cycle state

modes = [MODE_NORMAL, MODE_TURBO, MODE_QUIET, CODE_STOP] # Cycle list

idx = 0 # Current index

def now_ms(): # Helper: current ms

return time.ticks_ms() # Return ms ticks

def can_send(): # Helper: spacing check

elapsed = time.ticks_diff(now_ms(), last_send_ms) # Elapsed since last send

return elapsed >= (base_gap_ms + extra_gap_ms) # Compare against gap

def mark_sent(): # Helper: mark send time

global last_send_ms # Use global timestamp

last_send_ms = now_ms() # Update last send

def bump_gap(): # Helper: increase adaptive gap

global extra_gap_ms # Use global gap

extra_gap_ms = min(extra_gap_ms + 50, 300) # Increase up to 300 ms

def reduce_gap(): # Helper: reduce adaptive gap

global extra_gap_ms # Use global gap

extra_gap_ms = max(extra_gap_ms - 20, 0) # Reduce down to 0 ms

def send_ir(code): # Helper: send IR packet

ir_tx.transmit(0x00, code, 0x00) # Transmit code

print("[Controller] TX:", hex(code), # Serial: log send + gap

"| gap", base_gap_ms + extra_gap_ms, "ms")

mark_sent() # Mark send

reduce_gap() # Lightly reduce gap after send

print("[Controller] Remote loop start") # Serial: start controller

# Controller loop (run on the CONTROLLER)

while True: # Main controller loop

if pinA.value() == 0 and can_send(): # If A pressed and spaced

send_ir(CODE_FORWARD) # Send forward

if pinB.value() == 0 and can_send(): # If B pressed and spaced

send_ir(CODE_BACKWARD) # Send backward

if pinC.value() == 0 and can_send(): # If C pressed and spaced

send_ir(CODE_LEFT) # Send left

if pinD.value() == 0 and can_send(): # If D pressed and spaced

send_ir(CODE_RIGHT) # Send right

if pinF.value() == 0 and can_send(): # If F pressed and spaced

send_ir(CODE_STOP) # Send stop

bump_gap() # Increase gap to avoid flood

time.sleep_ms(200) # Debounce stop press

if pinE.value() == 0 and can_send(): # If E pressed (mode cycle)

idx = (idx + 1) % len(modes) # Advance index

send_ir(modes[idx]) # Send mode code

time.sleep_ms(250) # Debounce for mode switch

time.sleep_ms(40) # Short poll delay

# ---------- ROBOT (R32 #2) ----------

# NOTE: Run the following robot code on the second R32 board.

import irremote # Load IR library

import machine # Load hardware pin/PWM library

import time # Load time library

# Optional Bluetooth feedback:

import ble_peripheral # Load Bluetooth peripheral helper

import ble_handle # Load Bluetooth handle helper

# IR RX setup

ir_rx = irremote.NEC_RX(26, 8) # IR receiver on Pin 26

print("[Robot] IR RX ready") # Serial: IR initialized

# Motor pins (L298N)

in1 = machine.Pin(23, machine.Pin.OUT) # IN1 left

in2 = machine.Pin(19, machine.Pin.OUT) # IN2 left

in3 = machine.Pin(13, machine.Pin.OUT) # IN3 right

in4 = machine.Pin(21, machine.Pin.OUT) # IN4 right

print("[Robot] Direction pins set") # Serial: direction pins ready

# PWM pins (L298N enables)

pwmA = machine.PWM(machine.Pin(5)) # ENA PWM

pwmB = machine.PWM(machine.Pin(18)) # ENB PWM

pwmA.freq(2000) # PWM freq

pwmB.freq(2000) # PWM freq

speed = 650 # Start medium duty

pwmA.duty(speed) # Apply left duty

pwmB.duty(speed) # Apply right duty

print("[Robot] Start duty =", speed) # Serial: duty init

# Optional BLE ACK setup

ble_p = ble_peripheral.BLESimplePeripheral('Robot-R32') # Bluetooth peripheral

handle = ble_handle.Handle() # Callback handle

print("[Robot] BLE 'Robot-R32' ready") # Serial: BLE initialized

# Codes (must match controller)

CODE_FORWARD = 0x18 # Forward

CODE_BACKWARD = 0x52 # Backward

CODE_LEFT = 0x08 # Left

CODE_RIGHT = 0x5A # Right

CODE_STOP = 0x19 # Stop

MODE_TURBO = 0x55 # Turbo

MODE_QUIET = 0x16 # Quiet

MODE_NORMAL = 0x46 # Normal

def ack(label): # Helper: send ACK via BLE

ble_p.send("ACK:" + str(label)) # Send ACK string

print("[Robot] ACK:", label) # Serial: log ACK

def stop_all(): # Helper: stop motors

in1.value(0) # Left IN1 OFF

in2.value(0) # Left IN2 OFF

in3.value(0) # Right IN3 OFF

in4.value(0) # Right IN4 OFF

print("[Robot] STOP") # Serial: stopped

def drive_forward(): # Helper: forward motion

in1.value(1) # Left forward ON

in2.value(0) # Left backward OFF

in3.value(1) # Right forward ON

in4.value(0) # Right backward OFF

print("[Robot] FORWARD") # Serial: forward

def drive_backward(): # Helper: backward motion

in1.value(0) # Left forward OFF

in2.value(1) # Left backward ON

in3.value(0) # Right forward OFF

in4.value(1) # Right backward ON

print("[Robot] BACKWARD") # Serial: backward

def turn_left(): # Helper: spin left

in1.value(0) # Left forward OFF

in2.value(1) # Left backward ON

in3.value(1) # Right forward ON

in4.value(0) # Right backward OFF

print("[Robot] LEFT") # Serial: left turn

def turn_right(): # Helper: spin right

in1.value(1) # Left forward ON

in2.value(0) # Left backward OFF

in3.value(0) # Right forward OFF

in4.value(1) # Right backward ON

print("[Robot] RIGHT") # Serial: right turn

def apply_mode(code): # Helper: set PWM speed by mode

global speed # Use global speed variable

if code == MODE_TURBO: # If turbo

speed = 1023 # Max duty

print("[Robot] MODE TURBO duty", speed) # Serial: log turbo

ack("MODE:TURBO") # ACK turbo

elif code == MODE_QUIET: # If quiet

speed = 400 # Low duty

print("[Robot] MODE QUIET duty", speed) # Serial: log quiet

ack("MODE:QUIET") # ACK quiet

elif code == MODE_NORMAL: # If normal

speed = 650 # Medium duty

print("[Robot] MODE NORMAL duty", speed) # Serial: log normal

ack("MODE:NORMAL") # ACK normal

elif code == CODE_STOP: # If stop mode code used

speed = 0 # Duty zero

print("[Robot] MODE STOP duty", speed) # Serial: log stop

ack("MODE:STOP") # ACK stop

pwmA.duty(speed) # Apply left duty

pwmB.duty(speed) # Apply right duty

print("[Robot] Control loop start") # Serial: start robot loop

# Robot loop (run on the ROBOT)

while True: # Main robot loop

if ir_rx.any(): # If code available

code = ir_rx.code[0] # Read IR code

print("[Robot] IR:", hex(code)) # Serial: show code

if code == CODE_FORWARD: # If forward

drive_forward() # Drive forward

ack("CMD:FORWARD") # ACK forward

elif code == CODE_BACKWARD: # If backward

drive_backward() # Drive backward

ack("CMD:BACKWARD") # ACK backward

elif code == CODE_LEFT: # If left

turn_left() # Spin left

ack("CMD:LEFT") # ACK left

elif code == CODE_RIGHT: # If right

turn_right() # Spin right

ack("CMD:RIGHT") # ACK right

elif code in (MODE_TURBO, MODE_QUIET, MODE_NORMAL, CODE_STOP): # If mode

apply_mode(code) # Apply mode

elif code == CODE_STOP: # If explicit stop command

stop_all() # Stop motors

ack("CMD:STOP") # ACK stop

else: # Unknown code

print("[Robot] UNKNOWN:", hex(code)) # Serial: warn

ble_p.send("ERR:UNKNOWN:" + hex(code)) # Send error feedback

time.sleep_ms(150) # Loop delay for responsiveness

📖 External explanation

- What it teaches: A clean remote → robot architecture with reliable commands, modes, and feedback.

- Why it works: IR is simple and robust for one-way control; PWM sets speeds; clear helpers keep behavior understandable; BLE ACKs give confidence.

- Key concept: Separate concerns — controller focuses on inputs and command cadence; robot focuses on actuation and status.

✨ Story time

You’ve built a rover squad: the hand-held commander (controller R32) and the responsive rover (robot R32). A quick tap, a clean beam, a solid move — with a radio “ACK” to say “got it!”

🕵️ Debugging (2)

🐞 Debugging 3.8.A – Excessive delay

- Symptom: Commands feel laggy; robot moves late.

- Check: Controller’s adaptive gap too high or long sleeps; robot loop sleeps too long.

- Fix:

# Controller: keep base_gap_ms ~200 and extra_gap_ms <= 300

time.sleep_ms(40) # Poll fast; avoid long sleeps

# Robot: keep loop delay short

time.sleep_ms(150) # Responsive read frequency

🐞 Debugging 3.8.B – Incorrect feedback

- Symptom: ACK says TURBO but speed feels quiet.

- Check: Mode codes mismatch or BLE ACK sent before PWM applied.

- Fix:

# Ensure constants match on both boards

MODE_TURBO = 0x55

MODE_QUIET = 0x16

MODE_NORMAL = 0x46

CODE_STOP = 0x19

# Apply PWM before ACK, or confirm after set:

apply_mode(code) # Sets PWM

ack("MODE:TURBO") # Then send ACK (order matters)

✅ Final checklist

- Controller buttons A–D control directions; F stops; E cycles modes.

- Robot decodes IR and moves correctly with IN1–IN4.

- PWM speed changes with Turbo/Quiet/Normal/Stop.

- Feedback logs and optional BLE ACKs match actions.

- Adaptive spacing keeps control responsive without flooding.

📚 Extras

- 🧠 Student tip: Start at “Normal” mode, then test Turbo/Quiet to feel the difference.

- 🧑🏫 Instructor tip: Have pairs swap roles — one controls, one watches logs for ACKs/errors.

- 📖 Glossary:

- IR: Infrared light used for simple remote commands.

- PWM duty: Percentage of power; controls speed.

- ACK: Short message confirming an action or mode.

- 💡 Mini tips:

- Keep IR modules aligned and at 20–50 cm distance in bright rooms.

- Print short logs only; verbose prints slow loops.

- Share GND across controller, robot, and motor driver.