Project 6.12: "Integration N1 to N6"

What you’ll learn

- ✅ Line sensing: Read a 3–5 IR reflectance array, normalize values, and detect the line position.

- ✅ Error and PID control: Compute lateral error and use P–I–D terms to steer smoothly.

- ✅ Motor mixing: Convert steering output into left/right wheel speeds with safe limits and ramps.

- ✅ Auto‑tune basics: Run a step test to estimate gains and prevent oscillations.

- ✅ Lap timing + logging: Time laps, log parameters and performance, and replay settings.

Blocks glossary (used in this project)

- IR reflectance inputs: Analog reads from sensor array pins (e.g., 32/33/34/35/36).

- Normalization: Map raw ADC 0–4095 to 0.0–1.0 and clamp.

- Line position estimate: Weighted center index or threshold hit.

- PID controller: (u = K_p e + K_i int e , dt + K_d frac{de}{dt}) for steering output.

- Motor mixing: Base speed ± steering with min/max clamps and acceleration ramp.

- Serial println: Short tags: “SENS:…”, “ERR:…”, “PID:…”, “MIX:…”, “LAP:…”, “LOG:…”, “SAFE:…”.

What you need

| Part | How many? | Pin connection / Notes |

|---|---|---|

| D1 R32 (ESP32) | 1 | USB cable (30 cm) |

| IR reflectance array (3–5 sensors) | 1 set | e.g., A0→Pin 32, A1→33, A2→34, A3→35, A4→36 |

| L298N + TT motors | 1 set | Left IN1→18, IN2→19; Right IN3→5, IN4→23 |

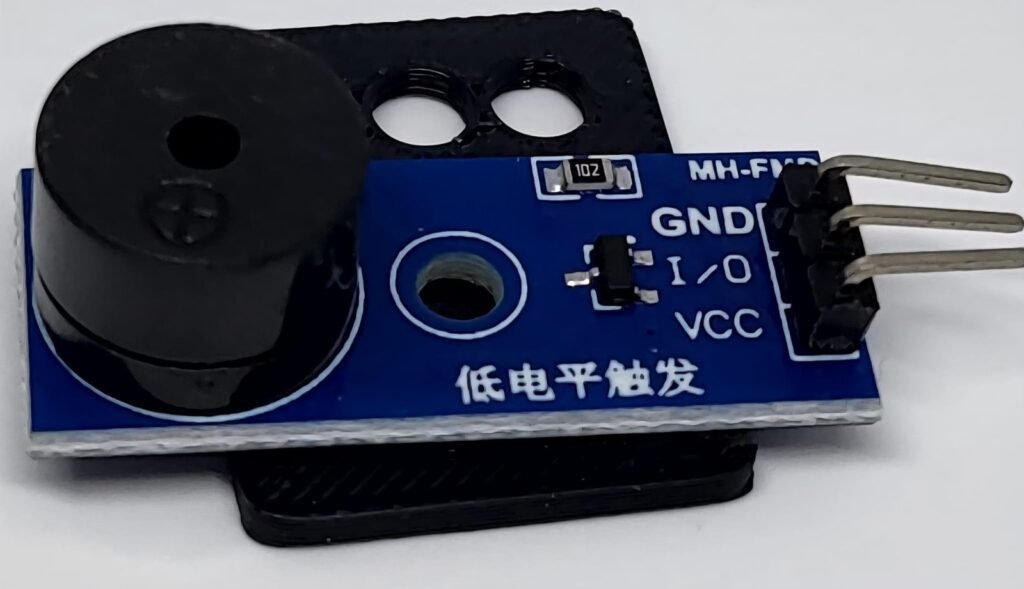

| LED + buzzer (optional) | 1 each | LED → Pin 13, Buzzer → Pin 23 |

| Track line (black tape on white) | 1 | High contrast for easier sensing |

Notes

- Keep sensor array 3–5 mm above the surface; align straight across the robot’s front.

- Share ground between sensors, R32, and motor driver.

- If using 5 sensors, adjust the arrays and weights accordingly.

Before you start

- Array mounted and wired to ADC pins

- Motors wired; wheels spin freely

- Serial monitor open and shows:

print("Ready!") # Confirm serial is working so you can see messages

Microprojects 1–5

Microproject 6.12.1 – Reading and normalizing the IR array

Goal: Read 3–5 sensors, normalize to 0.0–1.0, and print a clean snapshot.

Blocks used:

- ADC read: 12‑bit.

- Normalization: value/4095, clamp 0–1.

MicroPython code:

import machine # Import machine for ADC pins

import time # Import time for small delays

# ADC sensors: adjust for 3–5 channels as available

pins = [32, 33, 34, 35, 36] # Define ADC-capable pins for the array

adcs = [] # Create a list to store ADC objects

for p in pins: # Iterate over each pin number

a = machine.ADC(machine.Pin(p)) # Create ADC object on pin p

a.atten(machine.ADC.ATTN_11DB) # Set 11 dB attenuation for wider range

a.width(machine.ADC.WIDTH_12BIT) # Set 12-bit resolution (0–4095)

adcs.append(a) # Append ADC object to list

print("SENS:READY", pins) # Print sensor pin setup

def read_norm(): # Define function to read and normalize sensors

vals = [] # Create list for normalized values

for a in adcs: # Iterate over each ADC object

raw = a.read() # Read raw 12-bit value

norm = max(0.0, min(1.0, raw / 4095.0)) # Normalize and clamp to 0–1

vals.append(round(norm, 3)) # Append rounded normalized value

print("SENS:NORM", vals) # Print normalized array snapshot

return vals # Return normalized values list

snap = read_norm() # Take one normalized reading

time.sleep(0.1) # Short delay for readability

Reflection: Normalized values make the array easy to read and compare between sensors.

Challenge:

- Easy: Print raw values and normalized together.

- Harder: Add per‑sensor calibration offsets and scales.

Microproject 6.12.2 – Estimating line position and error

Goal: Compute a weighted center index and error around the middle sensor.

Blocks used:

- Weights: Use indices −2…+2 or −1…+1.

- Threshold: Consider dark line as “high” or “low” depending on sensor type.

MicroPython code:

# Choose interpretation: if dark increases reading, set DARK_HIGH=True

DARK_HIGH = True # Define whether dark line yields higher normalized numbers

weights = [-2, -1, 0, 1, 2] # Define weights for a 5-sensor array (adjust for 3-sensor case)

print("ERR:WEIGHTS", weights) # Print weights

def line_pos(vals): # Define function to estimate line position

# If dark is low, invert values for weighting

use = vals if DARK_HIGH else [1.0 - v for v in vals] # Build weighted values list

total = sum(use) + 1e-6 # Compute sum with small epsilon to avoid zero

pos = 0.0 # Initialize position accumulator

for w, v in zip(weights, use): # Iterate over weight and value pairs

pos += w * v # Accumulate weighted position

center = pos / total # Normalize by total

print("ERR:POS", round(center, 3)) # Print estimated position (negative=left)

return center # Return center position

vals = read_norm() # Read normalized sensor array

center = line_pos(vals) # Compute line position estimate

err = -center # Define control error (positive means steer right)

print("ERR:VAL", round(err, 3)) # Print control error

Reflection: A simple weighted center turns many sensors into one clean steering signal.

Challenge:

- Easy: Switch DARK_HIGH to match your array behavior.

- Harder: If total is below a threshold, print “ERR:LOST_LINE”.

Microproject 6.12.3 – Building a PID controller

Goal: Implement P–I–D for steering with clamps and integral windup protection.

Blocks used:

- P/I/D terms: Kp, Ki, Kd; store integral and last error.

- Clamps: Limit u and integral range.

MicroPython code:

import time # Import time for dt

Kp = 1.4 # Set proportional gain

Ki = 0.0 # Set integral gain (start at 0 to tune later)

Kd = 0.08 # Set derivative gain

i_sum = 0.0 # Initialize integral sum term

last_err = 0.0 # Initialize last error for derivative

print("PID:GAINS", Kp, Ki, Kd) # Print initial gains

def pid_step(err, dt): # Define PID step function

global i_sum, last_err # Use global integral and last error

p = Kp * err # Compute proportional term

i_sum += err * dt # Accumulate integral with dt

i_sum = max(-1.0, min(1.0, i_sum)) # Clamp integral to avoid windup

i = Ki * i_sum # Compute integral contribution

d = Kd * ((err - last_err) / dt if dt > 0 else 0.0) # Compute derivative term

u = p + i + d # Sum PID terms for control output

u = max(-1.0, min(1.0, u)) # Clamp output to −1..+1

last_err = err # Update last error for next step

print("PID:STEP p", round(p, 3), "i", round(i, 3), "d", round(d, 3), "u", round(u, 3)) # Print terms

return u # Return control output

# Demo one step with fake dt

dt = 0.05 # Define sample time in seconds

u = pid_step(err, dt) # Compute control output

Reflection: Printing each PID term helps students see what the controller is “thinking.”

Challenge:

- Easy: Enable Ki (e.g., 0.02) and observe integral behavior.

- Harder: Add an “integral freeze” when line is lost.

Microproject 6.12.4 – Motor mixing and ramping

Goal: Convert steering output to left/right speeds with limits and ramps.

Blocks used:

- Base speed: Set forward speed fraction.

- Ramp: Limit change per step to reduce jerks.

MicroPython code:

import machine # Import machine for motor pins

import time # Import time for pulse durations

# Motor pins for L298N driver

L_IN1 = machine.Pin(18, machine.Pin.OUT) # Left IN1

L_IN2 = machine.Pin(19, machine.Pin.OUT) # Left IN2

R_IN3 = machine.Pin(5, machine.Pin.OUT) # Right IN3

R_IN4 = machine.Pin(23, machine.Pin.OUT) # Right IN4

print("MOTORS:READY 18/19 5/23") # Print motor pins ready

base = 0.6 # Set base forward speed fraction (0..1)

last_l = 0.0 # Initialize last left speed fraction

last_r = 0.0 # Initialize last right speed fraction

ramp = 0.2 # Set max change per step (fraction)

pulse_ms = 120 # Set pulse duration per step in milliseconds

print("MIX:BASE", base, "RAMP", ramp) # Print mixing config

def clamp(x): # Define clamp helper for speed fractions

return max(0.0, min(1.0, x)) # Clamp to 0..1

def apply_mix(u): # Define function to apply steering mix

global last_l, last_r # Use global last speeds

l_target = clamp(base + u) # Compute left target fraction

r_target = clamp(base - u) # Compute right target fraction

dl = max(-ramp, min(ramp, l_target - last_l)) # Limit left change by ramp

dr = max(-ramp, min(ramp, r_target - last_r)) # Limit right change by ramp

l = clamp(last_l + dl) # Compute new left fraction

r = clamp(last_r + dr) # Compute new right fraction

print("MIX:LR", round(l, 2), round(r, 2)) # Print left/right fractions

last_l, last_r = l, r # Update last speeds

drive_pulse(l, r, pulse_ms) # Drive motors for one pulse

def drive_pulse(lf, rf, ms): # Define motor driving for one pulse

# Left motor direction: forward only for simplicity

L_IN1.value(1 if lf > 0 else 0) # Set left forward HIGH if lf > 0

L_IN2.value(0) # Keep left backward LOW

# Right motor direction: forward only

R_IN3.value(1 if rf > 0 else 0) # Set right forward HIGH if rf > 0

R_IN4.value(0) # Keep right backward LOW

print("MOVE:PULSE", ms, "LF", round(lf, 2), "RF", round(rf, 2)) # Print pulse info

time.sleep(ms / 1000.0) # Run motors for ms/1000 seconds

# Stop after pulse

L_IN1.value(0) # Set left forward LOW

R_IN3.value(0) # Set right forward LOW

print("MOVE:STOP") # Print stop

apply_mix(u) # Apply one mix from PID output

Reflection: Ramping avoids sudden jerks—robots feel smooth and controlled.

Challenge:

- Easy: Add reverse direction when rf or lf falls below 0.1 for tight turns.

- Harder: Implement a soft brake by pulsing the opposite direction briefly.

Microproject 6.12.5 – Step test auto‑tune basics

Goal: Run a step input, record response, and suggest Kp/Kd ranges.

Blocks used:

- Step: Drive a fixed u for N pulses.

- Metrics: Max overshoot, settling hint.

MicroPython code:

import time # Import time for timing

resp = [] # Create list to store (t, err, u) triplets

print("TUNE:START") # Print start of tuning

def step_run(u_fixed=0.3, steps=10): # Define step test runner

global last_err # Use last_err for derivative continuity

dt = 0.06 # Define sample time per step

for i in range(steps): # Iterate step count

vals = read_norm() # Read sensors

center = line_pos(vals) # Compute line center

err = -center # Compute error

u = pid_step(err, dt) if i > 0 else u_fixed # Use fixed on first, then PID

apply_mix(u) # Apply mixing to motors

resp.append((i * dt, err, u)) # Append response tuple

time.sleep(0.02) # Short gap for logging

step_run(0.3, 12) # Run a short step test

# Simple suggestion: if overshoot visible, reduce Kp or increase Kd

overs = max(abs(e) for _, e, _ in resp) # Compute max absolute error

print("TUNE:OVERSHOOT", round(overs, 3)) # Print overshoot

if overs > 1.5: # If overshoot too large

print("TUNE:SUGGEST Kp ->", round(Kp * 0.8, 3), "Kd ->", round(Kd * 1.2, 3)) # Print suggestion

else: # If overshoot acceptable

print("TUNE:SUGGEST OK") # Print OK suggestion

Reflection: Even a tiny step test teaches students how gains change behavior.

Challenge:

- Easy: Log resp to a file for later plotting.

- Harder: Compute a settling time and print “TUNE:SETTLED_MS”.

Main project – PID line follower with auto‑tune and logging

Blocks steps (with glossary)

- Sensor read + normalize: Clean array snapshot on each cycle.

- Line position + error: Weighted center with LOST_LINE guard.

- PID controller: P–I–D with windup clamp and printed terms.

- Motor mixing + ramp: Base speed ± u, clamped, pulsed.

- Auto‑tune: Short step test to refine Kp/Kd.

- Lap timing + logging: Log laps, gains, and summaries.

MicroPython code (mirroring blocks)

# Project 6.12 – PID Line Follower (Sensors + PID + Mix + Auto-tune + Logging)

import machine # Import machine for ADC and motor pins

import time # Import time for dt, laps, and logging

# ===== Sensors (ADC array) =====

pins = [32, 33, 34, 35, 36] # Define sensor pins

adcs = [] # Create ADC objects list

for p in pins: # Iterate pins

a = machine.ADC(machine.Pin(p)) # Create ADC on pin

a.atten(machine.ADC.ATTN_11DB) # Set attenuation

a.width(machine.ADC.WIDTH_12BIT) # Set resolution

adcs.append(a) # Append to list

print("INIT:SENS", pins) # Print sensor init

DARK_HIGH = True # Define dark line interpretation

weights = [-2, -1, 0, 1, 2] # Define weights for 5 sensors

print("INIT:WEIGHTS", weights) # Print weights

def read_norm(): # Read normalized sensor values

vals = [] # Create normalized list

for a in adcs: # Iterate sensors

raw = a.read() # Read raw

norm = max(0.0, min(1.0, raw / 4095.0)) # Normalize 0..1

vals.append(norm) # Append value

print("SENS:NORM", [round(v, 3) for v in vals]) # Print normalized

return vals # Return list

def line_pos(vals): # Estimate line position

use = vals if DARK_HIGH else [1.0 - v for v in vals] # Choose values

total = sum(use) + 1e-6 # Sum with epsilon

pos = 0.0 # Initialize position

for w, v in zip(weights, use): # Iterate pairs

pos += w * v # Accumulate weighted

center = pos / total # Normalize by total

print("ERR:POS", round(center, 3)) # Print position

return center # Return position

# ===== PID controller =====

Kp = 1.4 # Set proportional gain

Ki = 0.0 # Set integral gain

Kd = 0.08 # Set derivative gain

i_sum = 0.0 # Initialize integral storage

last_err = 0.0 # Initialize last error

print("INIT:PID", Kp, Ki, Kd) # Print gains

def pid_step(err, dt): # Compute PID output

global i_sum, last_err # Use globals

p = Kp * err # Proportional

i_sum += err * dt # Integrate

i_sum = max(-1.0, min(1.0, i_sum)) # Clamp integral

i = Ki * i_sum # Integral term

d = Kd * ((err - last_err) / dt if dt > 0 else 0.0) # Derivative

u = p + i + d # Sum

u = max(-1.0, min(1.0, u)) # Clamp output

last_err = err # Update last error

print("PID:STEP p", round(p, 3), "i", round(i, 3), "d", round(d, 3), "u", round(u, 3)) # Print terms

return u # Return control

# ===== Motors and mixing =====

L_IN1 = machine.Pin(18, machine.Pin.OUT) # Left IN1

L_IN2 = machine.Pin(19, machine.Pin.OUT) # Left IN2

R_IN3 = machine.Pin(5, machine.Pin.OUT) # Right IN3

R_IN4 = machine.Pin(23, machine.Pin.OUT) # Right IN4

print("INIT:MOTORS 18/19 5/23") # Print motor pins

base = 0.6 # Base forward fraction

last_l = 0.0 # Last left fraction

last_r = 0.0 # Last right fraction

ramp = 0.2 # Max change per step

pulse_ms = 120 # Pulse duration per step

print("INIT:MIX base", base, "ramp", ramp, "pulse", pulse_ms) # Print mix init

def clamp(x): # Clamp fraction

return max(0.0, min(1.0, x)) # Clamp 0..1

def drive_pulse(lf, rf, ms): # Drive motors for a pulse

L_IN1.value(1 if lf > 0 else 0) # Left forward HIGH if lf>0

L_IN2.value(0) # Left backward LOW

R_IN3.value(1 if rf > 0 else 0) # Right forward HIGH if rf>0

R_IN4.value(0) # Right backward LOW

print("MOVE:PULSE", ms, "LF", round(lf, 2), "RF", round(rf, 2)) # Print pulse info

time.sleep(ms / 1000.0) # Run motors

L_IN1.value(0) # Left forward LOW

R_IN3.value(0) # Right forward LOW

print("MOVE:STOP") # Print stop

def apply_mix(u): # Apply steering mix

global last_l, last_r # Use last fractions

l_target = clamp(base + u) # Left target

r_target = clamp(base - u) # Right target

dl = max(-ramp, min(ramp, l_target - last_l)) # Left ramp

dr = max(-ramp, min(ramp, r_target - last_r)) # Right ramp

l = clamp(last_l + dl) # New left

r = clamp(last_r + dr) # New right

print("MIX:LR", round(l, 2), round(r, 2)) # Print fractions

last_l, last_r = l, r # Update last

drive_pulse(l, r, pulse_ms) # Drive motors

# ===== Logging + laps =====

log_name = "pid_lap.txt" # Log filename

laps = 0 # Lap counter

t_lap_start = time.ticks_ms() # Lap start time

print("INIT:LOG", log_name) # Print log file

def log_write(line): # Write log line

try: # Try open

with open(log_name, "a") as f: # Open append

f.write(line + "n") # Write with newline

print("LOG:WRITE", line) # Print written

except OSError: # On error

print("LOG:ERR") # Print error

def mark_lap(): # Mark a lap

global laps, t_lap_start # Use globals

now = time.ticks_ms() # Current ms

lap_ms = time.ticks_diff(now, t_lap_start) # Lap duration

laps += 1 # Increment laps

t_lap_start = now # Reset start

print("LAP:MS", lap_ms, "LAPS", laps) # Print lap

log_write("LAP ms=" + str(lap_ms) + " laps=" + str(laps)) # Log lap

# ===== Auto-tune (short) =====

def step_tune(steps=10): # Run a short tune

dt = 0.06 # Sample time

for i in range(steps): # Iterate steps

vals = read_norm() # Read sensors

center = line_pos(vals) # Compute center

err = -center # Compute error

u = pid_step(err, dt) # Compute PID

apply_mix(u) # Apply mix

time.sleep(0.02) # Short gap

print("TUNE:DONE") # Print done

# ===== Main follow loop =====

print("RUN:PID FOLLOW") # Announce start

log_write("START Kp=" + str(Kp) + " Ki=" + str(Ki) + " Kd=" + str(Kd)) # Log gains

for _ in range(20): # Optional pre-run tune pulses

step_tune(steps=4) # Run small tune

time.sleep(0.05) # Short pause

# Main control loop

while True: # Continuous line follow

start = time.ticks_ms() # Timestamp before cycle

vals = read_norm() # Read sensors

center = line_pos(vals) # Compute center

# Detect lost line by total reflectance magnitude

total = sum(vals) # Sum normalized values

if total < 0.2: # If too low (likely off track)

print("SAFE:LOST_LINE") # Print lost line

# Reduce base and slow for recovery

base = max(0.4, base - 0.1) # Lower base speed

apply_mix(0.0) # Drive straight slow pulse

time.sleep(0.1) # Pause

continue # Skip PID step this cycle

err = -center # Compute error

dt = max(0.02, (time.ticks_ms() - start) / 1000.0) # Compute dt seconds

u = pid_step(err, dt) # Compute PID output

apply_mix(u) # Apply motor mix

# Lap heuristic: center near zero for sustained period

if abs(center) < 0.2 and total > 0.6: # If near middle, strong signal

mark_lap() # Mark a lap

time.sleep(0.02) # Small pacing delay

External explanation

- What it teaches: You built a complete line follower: sensor normalization, weighted line position, PID steering, smooth motor mixing with ramps, a quick auto‑tune step test, and lap timing with logs.

- Why it works: The weighted center compresses many sensors into one error; PID stabilizes steering; ramps keep motion gentle; a simple tune loop reveals how gains affect behavior; logging makes progress visible.

- Key concept: “Sense → estimate → control → move → measure.”

Story time

Tape on the floor becomes a path. Your robot reads the stripes, nudges left and right—never jerky, just confident. A lap completes, the printout smiles: LAP:MS 4382. You tweak Kp by a hair and watch it glide even cleaner.

Debugging (2)

Debugging 6.12.1 – Robot oscillates left/right

Problem: It wiggles and can’t settle on the line.

Clues: PID:STEP shows large p and d flipping signs quickly.

Broken code:

Kp = 2.8 # Too high

Kd = 0.0 # No damping

Fixed code:

Kp = 1.4 # Moderate proportional

Kd = 0.08 # Add derivative damping

print("DEBUG:GAINS", Kp, Kd) # Verify tuned gains

Why it works: Lower proportional plus derivative damping reduces overshoot and oscillations.

Avoid next time: Tune Kp up slowly, add Kd when you see overshoot.

Debugging 6.12.2 – Loses the line on tight turns

Problem: Turns are too slow or steering saturates at ±1.

Clues: MIX:LR clamps at 0/1 often; SAFE:LOST_LINE prints.

Broken code:

ramp = 0.05 # Changes too small; can’t keep up

Fixed code:

ramp = 0.2 # Allow faster changes per step

base = 0.6 # Keep base speed reasonable

print("DEBUG:MIX ramp", ramp, "base", base) # Confirm mix settings

Why it works: A larger ramp lets the robot update wheel speeds fast enough to track the curve.

Avoid next time: Balance ramp and base—too fast causes jerk, too slow misses turns.

Final checklist

- Sensors print normalized values in a single clean snapshot

- Weighted center and ERR:POS behave as expected (left negative, right positive)

- PID prints p/i/d/u each cycle and clamps integral and output safely

- Motor mixing prints LF/RF and uses ramping to avoid jerks

- Auto‑tune runs a short step test and suggests gain changes

- Laps and logs record performance for classroom review

Extras

- 🧠 Student tip: Tape two tracks—one gentle, one tight. Tune Kp/Kd on the gentle, then test the tight and adjust ramp.

- 🧑🏫 Instructor tip: Have teams plot PID:STEP u over time and annotate where overshoot appears; connect plots to gain changes.

- 📖 Glossary:

- Weighted center: A single position estimate computed from multiple sensors.

- Windup: Integral term grows too large when the controller is saturated.

- Ramp: A limit on how fast outputs can change to stay smooth.

- 💡 Mini tips:

- Keep sensors at the same height; uneven spacing skews the center.

- Start with Ki = 0; add a little only if steady‑state error persists.

- Print totals and center—those two numbers explain most behavior.