Project 7.1: "Color Detector"

What you’ll learn

- ✅ Gray level sensing: Read an analog grayscale sensor and normalize brightness.

- ✅ Color inference by reflectance: Use an RGB light and one sensor to estimate basic colors.

- ✅ Color classification: Build thresholds for RED/GREEN/BLUE and UNKNOWN with confidence scoring.

- ✅ Color‑coded behaviors: Follow tape colors or trigger actions by color tags.

- ✅ Sorting integration: Drive a servo to sort items by detected color with clear prints.

Blocks glossary (used in this project)

- ADC read: 12‑bit analog input for light/reflectance level.

- Normalization: Map 0–4095 to 0.0–1.0 brightness.

- RGB illumination: Drive R/G/B LEDs to probe reflectance by color channel.

- Thresholds: Min/max values to classify channels and decide labels.

- Servo control: PWM to 0°, 90°, 180° for sorting positions.

- Serial println: Print short tags “SENS:…”, “NORM:…”, “RGB:…”, “COLOR:…”, “CONF:…”, “SORT:…”, “FOLLOW:…”.

What you need

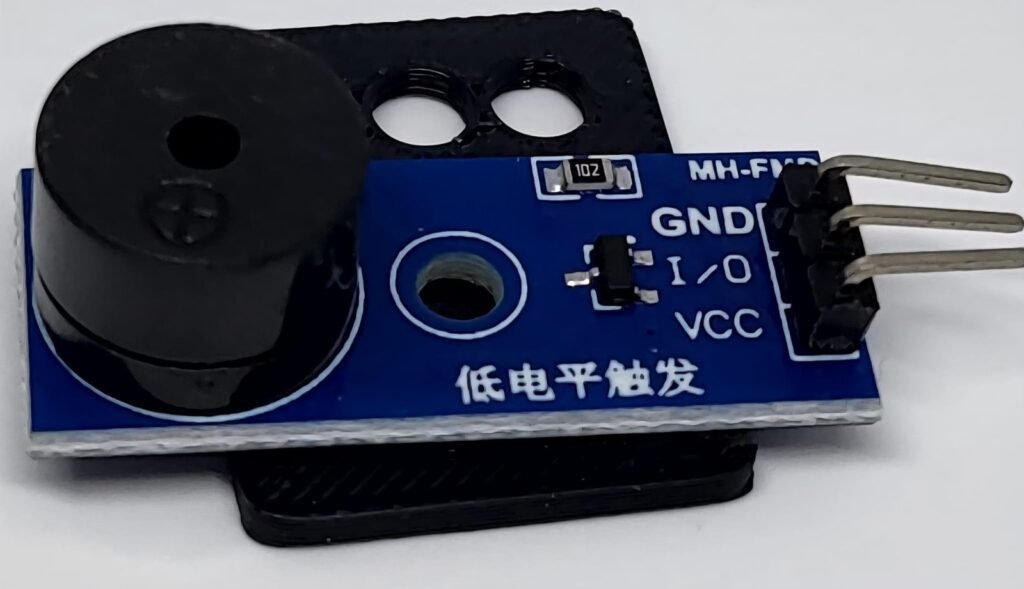

| Part | How many? | Pin connection / Notes |

|---|---|---|

| D1 R32 (ESP32) | 1 | USB cable (30 cm) |

| Analog grayscale sensor | 1 | OUT → Pin 34 (ADC), VCC, GND |

| RGB LED (common cathode) | 1 | R→Pin 14, G→Pin 27, B→Pin 26 (with resistors) |

| Servo (SG90) | 1 | Signal → Pin 13, VCC (5V), GND (shared) |

| Optional motors (line follow) | 1 set | L298N: Left IN1→18, IN2→19; Right IN3→5, IN4→23 |

Notes

- Use current‑limiting resistors (e.g., 220–330 Ω) for R/G/B LED pins.

- Keep the sensor at a fixed height over the surface (3–8 mm) for stable readings.

- Share ground across ESP32, LED, servo, sensor, and motor driver.

Before you start

- Sensor wired to Pin 34; RGB LED to 14/27/26; servo to Pin 13

- Place colored test cards (red, green, blue) and a white reference nearby

- Serial monitor open and shows:

print("Ready!") # Confirm serial is working so you can see messages

Microprojects 1–5

Microproject 7.1.1 – Detection of gray levels

Goal: Read the analog sensor, normalize brightness, and print a clean snapshot.

Blocks used:

- ADC read: Light level.

- Normalization: 0–1 value.

MicroPython code:

import machine # Import machine to access ADC and pins

import time # Import time for small delays

adc = machine.ADC(machine.Pin(34)) # Create ADC on Pin 34 for grayscale sensor

adc.atten(machine.ADC.ATTN_11DB) # Set attenuation for wider voltage range

adc.width(machine.ADC.WIDTH_12BIT) # Set 12-bit resolution (0–4095)

print("SENS:ADC READY PIN=34") # Print sensor readiness

def read_gray(): # Define function to read and normalize grayscale value

raw = adc.read() # Read raw ADC count (0–4095)

norm = max(0.0, min(1.0, raw / 4095.0)) # Normalize to 0.0–1.0 and clamp

print("SENS:RAW", raw, "NORM:", round(norm, 3)) # Print raw and normalized values

return norm # Return normalized brightness

val = read_gray() # Take one reading

time.sleep(0.2) # Short delay for readability

Reflection: Normalization turns sensor counts into an easy brightness scale anyone can read.

Challenge:

- Easy: Print a bar “#####” scaled to brightness.

- Harder: Record min/max across 50 samples to auto‑calibrate.

Microproject 7.1.2 – Differentiation of basic colors by RGB illumination

Goal: Light the scene with red, green, and blue LEDs separately and record reflectance.

Blocks used:

- GPIO outputs: Drive R/G/B pins.

- Sequenced sampling: Take time‑spaced readings per channel.

MicroPython code:

import machine # Import machine for Pin outputs

import time # Import time for delays

ledR = machine.Pin(14, machine.Pin.OUT) # Create red LED control on Pin 14

ledG = machine.Pin(27, machine.Pin.OUT) # Create green LED control on Pin 27

ledB = machine.Pin(26, machine.Pin.OUT) # Create blue LED control on Pin 26

print("RGB:PINS R=14 G=27 B=26") # Print LED pin setup

def sample_channel(pin_on): # Define helper to sample sensor under a specific LED

ledR.value(0) # Ensure red LED is OFF

ledG.value(0) # Ensure green LED is OFF

ledB.value(0) # Ensure blue LED is OFF

pin_on.value(1) # Turn ON the selected LED

time.sleep(0.05) # Wait for light to stabilize

val = read_gray() # Read normalized brightness with current illumination

pin_on.value(0) # Turn OFF the selected LED

return val # Return channel brightness

r = sample_channel(ledR) # Sample reflectance under red light

g = sample_channel(ledG) # Sample reflectance under green light

b = sample_channel(ledB) # Sample reflectance under blue light

print("RGB:SAMPLE R", round(r, 3), "G", round(g, 3), "B", round(b, 3)) # Print channel values

Reflection: A single sensor can “guess” colors by how bright they look under different colored lights.

Challenge:

- Easy: Repeat sampling 3× and average each channel.

- Harder: Add ambient measurement (all LEDs OFF) and subtract background.

Microproject 7.1.3 – Classifying objects by color

Goal: Build thresholds for RED/GREEN/BLUE and report label + confidence.

Blocks used:

- Thresholds: Per‑channel comparisons.

- Confidence: Margin between top and second channel.

MicroPython code:

thr = 0.05 # Set minimal difference threshold to consider a dominant color

print("COLOR:THR", thr) # Print threshold setting

def classify_rgb(r, g, b): # Define function to classify color based on channel values

vals = {"RED": r, "GREEN": g, "BLUE": b} # Create dict of channel values

sorted_items = sorted(vals.items(), key=lambda kv: kv[1], reverse=True) # Sort channels by brightness

top_label, top_val = sorted_items[0] # Extract top channel label and value

second_val = sorted_items[1][1] # Extract second highest value

margin = top_val - second_val # Compute margin between top and second

conf = max(0.0, round(margin, 3)) # Compute non-negative confidence score

if conf < thr: # If margin below threshold

label = "UNKNOWN" # Assign unknown label

else: # If margin sufficient

label = top_label # Assign dominant color label

print("COLOR:CLASS", label, "CONF:", conf, "R/G/B:", round(r,3), round(g,3), round(b,3)) # Print classification line

return label, conf # Return label and confidence

label, conf = classify_rgb(r, g, b) # Classify sampled channels

Reflection: Confidence is your honesty meter—small margins mean “not sure,” and that’s okay.

Challenge:

- Easy: Add “WHITE” when all channels are high and balanced.

- Harder: Add “BLACK” when all channels are very low.

Microproject 7.1.4 – Color‑coded line follower (simple)

Goal: React to color tags on a track: RED=LEFT nudge, GREEN=RIGHT nudge, BLUE=FORWARD.

Blocks used:

- Mapping: Color → action.

- Motor helpers: Forward/left/right pulses.

MicroPython code:

import machine # Import machine for motor pins

import time # Import time for pulse durations

L_IN1 = machine.Pin(18, machine.Pin.OUT) # Create left IN1 motor pin

L_IN2 = machine.Pin(19, machine.Pin.OUT) # Create left IN2 motor pin

R_IN3 = machine.Pin(5, machine.Pin.OUT) # Create right IN3 motor pin

R_IN4 = machine.Pin(23, machine.Pin.OUT) # Create right IN4 motor pin

print("MOTORS:READY 18/19 5/23") # Print motor setup

def motors_stop(): # Define function to stop both motors

L_IN1.value(0) # Set left IN1 LOW

L_IN2.value(0) # Set left IN2 LOW

R_IN3.value(0) # Set right IN3 LOW

R_IN4.value(0) # Set right IN4 LOW

print("MOVE:STOP") # Print stop action

def forward(ms=200): # Define forward pulse helper in milliseconds

L_IN1.value(1) # Set left forward HIGH

L_IN2.value(0) # Set left backward LOW

R_IN3.value(1) # Set right forward HIGH

R_IN4.value(0) # Set right backward LOW

print("MOVE:FWD", ms) # Print forward pulse

time.sleep(ms / 1000.0) # Run motors for ms duration

motors_stop() # Stop motors after pulse

def left(ms=160): # Define left turn pulse helper

L_IN1.value(0) # Set left forward LOW

L_IN2.value(1) # Set left backward HIGH

R_IN3.value(1) # Set right forward HIGH

R_IN4.value(0) # Set right backward LOW

print("MOVE:LEFT", ms) # Print left turn pulse

time.sleep(ms / 1000.0) # Run turn for ms

motors_stop() # Stop motors

def right(ms=160): # Define right turn pulse helper

L_IN1.value(1) # Set left forward HIGH

L_IN2.value(0) # Set left backward LOW

R_IN3.value(0) # Set right forward LOW

R_IN4.value(1) # Set right backward HIGH

print("MOVE:RIGHT", ms) # Print right turn pulse

time.sleep(ms / 1000.0) # Run turn for ms

motors_stop() # Stop motors

def react_by_color(label): # Define function to react to color label

if label == "RED": # If red detected

left(140) # Apply a small left nudge

elif label == "GREEN": # If green detected

right(140) # Apply a small right nudge

elif label == "BLUE": # If blue detected

forward(180) # Apply forward pulse

else: # If unknown color

print("FOLLOW:UNKNOWN") # Print unknown reaction

motors_stop() # Stop safely

react_by_color(label) # React to classified color

Reflection: Small nudges keep motion gentle—kids see action tied to colorful cues.

Challenge:

- Easy: Add “YELLOW” behavior as forward‑left.

- Harder: Use confidence to scale pulse (higher confidence = longer pulse).

Microproject 7.1.5 – Integration with sorting system

Goal: Move a servo to bins based on color labels.

Blocks used:

- PWM servo: 0°, 90°, 180° positions.

- Mapping: Color → angle.

MicroPython code:

import machine # Import machine for PWM servo

import time # Import time for delays

servo = machine.PWM(machine.Pin(13), freq=50) # Create PWM on Pin 13 at 50 Hz

print("SORT:SERVO READY PIN=13") # Print servo readiness

def angle_to_duty(angle): # Define function to map angle to PWM duty

us = 500 + int((angle / 180.0) * 2000) # Compute microseconds (0°=500us, 180°=2500us)

duty = int(us * 1023 / 20000) # Convert microseconds to duty (assuming 20 ms period)

print("SORT:DUTY", duty, "ANGLE", angle) # Print duty and angle

return duty # Return duty value

def sort_by_color(label): # Define function to move servo to bin by color

if label == "RED": # If red label

duty = angle_to_duty(0) # Compute duty for 0°

elif label == "GREEN": # If green label

duty = angle_to_duty(90) # Compute duty for 90°

elif label == "BLUE": # If blue label

duty = angle_to_duty(180) # Compute duty for 180°

else: # If unknown label

duty = angle_to_duty(45) # Compute duty for middle fallback

servo.duty(duty) # Apply duty to servo

print("SORT:MOVE", label) # Print sorting move

time.sleep(0.5) # Wait for servo to settle

sort_by_color(label) # Sort based on classified color

Reflection: Sorting turns measurement into a tangible result—“I see red; I place it left.”

Challenge:

- Easy: Blink the LED once in the color of the bin.

- Harder: Add a short “confirm” print with label and confidence.

Main project – Color detector and sorter

Blocks steps (with glossary)

- Gray read + normalization: Clean brightness snapshot.

- RGB probing: R/G/B channel reflectance via LED sequencing.

- Classification: Dominant channel with threshold and confidence.

- Color behaviors: Map label to motion or follow action.

- Sorting: Servo bins by color label, with fallback.

MicroPython code (mirroring blocks)

# Project 7.1 – Color Detector and Sorter (ADC + RGB probe + Classify + React + Servo)

import machine # Import machine for ADC, GPIO, PWM

import time # Import time for delays and sequencing

# ===== Sensor (ADC) =====

adc = machine.ADC(machine.Pin(34)) # Create ADC on Pin 34

adc.atten(machine.ADC.ATTN_11DB) # Set attenuation for full range

adc.width(machine.ADC.WIDTH_12BIT) # Set 12-bit resolution

print("INIT:SENS ADC=34") # Print sensor init

def read_gray(): # Define normalized gray read

raw = adc.read() # Read raw ADC value

norm = max(0.0, min(1.0, raw / 4095.0)) # Normalize 0..1

print("SENS:RAW", raw, "NORM", round(norm, 3)) # Print raw and norm

return norm # Return norm

# ===== RGB illumination =====

ledR = machine.Pin(14, machine.Pin.OUT) # Red LED pin

ledG = machine.Pin(27, machine.Pin.OUT) # Green LED pin

ledB = machine.Pin(26, machine.Pin.OUT) # Blue LED pin

print("INIT:RGB R=14 G=27 B=26") # Print RGB pins

def sample_channel(pin_on): # Define sample under one color

ledR.value(0) # Turn OFF red

ledG.value(0) # Turn OFF green

ledB.value(0) # Turn OFF blue

pin_on.value(1) # Turn ON selected color

time.sleep(0.05) # Stabilize illumination

val = read_gray() # Read brightness

pin_on.value(0) # Turn OFF selected color

return val # Return channel value

def sample_rgb(): # Define full RGB sampling

r = sample_channel(ledR) # Sample red channel

g = sample_channel(ledG) # Sample green channel

b = sample_channel(ledB) # Sample blue channel

print("RGB:VAL R", round(r,3), "G", round(g,3), "B", round(b,3)) # Print RGB values

return r, g, b # Return tuple

# ===== Classification =====

thr = 0.05 # Margin threshold for dominance

print("INIT:THR", thr) # Print threshold

def classify_rgb(r, g, b): # Define classification

vals = {"RED": r, "GREEN": g, "BLUE": b} # Channel dict

sorted_items = sorted(vals.items(), key=lambda kv: kv[1], reverse=True) # Sort by brightness

top_label, top_val = sorted_items[0] # Top label/value

second_val = sorted_items[1][1] # Second value

margin = top_val - second_val # Compute margin

conf = max(0.0, round(margin, 3)) # Confidence score

if conf < thr: # If margin too small

label = "UNKNOWN" # Unknown label

else: # Otherwise dominant

label = top_label # Dominant color label

print("COLOR:CLASS", label, "CONF", conf, "R/G/B", round(r,3), round(g,3), round(b,3)) # Print classification

return label, conf # Return label and confidence

# ===== Motors (optional follow) =====

L_IN1 = machine.Pin(18, machine.Pin.OUT) # Left IN1

L_IN2 = machine.Pin(19, machine.Pin.OUT) # Left IN2

R_IN3 = machine.Pin(5, machine.Pin.OUT) # Right IN3

R_IN4 = machine.Pin(23, machine.Pin.OUT) # Right IN4

print("INIT:MOTORS 18/19 5/23") # Print motors ready

def motors_stop(): # Define stop

L_IN1.value(0) # Left IN1 LOW

L_IN2.value(0) # Left IN2 LOW

R_IN3.value(0) # Right IN3 LOW

R_IN4.value(0) # Right IN4 LOW

print("MOVE:STOP") # Print stop

def forward(ms=180): # Define forward pulse

L_IN1.value(1) # Left forward HIGH

L_IN2.value(0) # Left backward LOW

R_IN3.value(1) # Right forward HIGH

R_IN4.value(0) # Right backward LOW

print("MOVE:FWD", ms) # Print forward

time.sleep(ms / 1000.0) # Run motors

motors_stop() # Stop motors

def left(ms=140): # Define left pulse

L_IN1.value(0) # Left forward LOW

L_IN2.value(1) # Left backward HIGH

R_IN3.value(1) # Right forward HIGH

R_IN4.value(0) # Right backward LOW

print("MOVE:LEFT", ms) # Print left

time.sleep(ms / 1000.0) # Run motors

motors_stop() # Stop motors

def right(ms=140): # Define right pulse

L_IN1.value(1) # Left forward HIGH

L_IN2.value(0) # Left backward LOW

R_IN3.value(0) # Right forward LOW

R_IN4.value(1) # Right backward HIGH

print("MOVE:RIGHT", ms) # Print right

time.sleep(ms / 1000.0) # Run motors

motors_stop() # Stop motors

def react_by_color(label, conf): # Define color behavior with confidence

scale = 1.0 + min(0.5, conf) # Scale pulses by confidence up to +50%

if label == "RED": # Red behavior

left(int(120 * scale)) # Left nudge scaled

elif label == "GREEN": # Green behavior

right(int(120 * scale)) # Right nudge scaled

elif label == "BLUE": # Blue behavior

forward(int(160 * scale)) # Forward scaled

else: # Unknown behavior

print("FOLLOW:UNKNOWN") # Print unknown

motors_stop() # Stop safely

# ===== Servo sorting =====

servo = machine.PWM(machine.Pin(13), freq=50) # Servo PWM at 50 Hz

print("INIT:SERVO PIN=13") # Print servo init

def angle_to_duty(angle): # Map angle to duty

us = 500 + int((angle / 180.0) * 2000) # Microseconds from angle

duty = int(us * 1023 / 20000) # Duty for 20 ms frame

print("SORT:MAP angle", angle, "duty", duty) # Print mapping

return duty # Return duty

def sort_by_color(label): # Move servo to bin

if label == "RED": # Red bin

servo.duty(angle_to_duty(0)) # 0°

elif label == "GREEN": # Green bin

servo.duty(angle_to_duty(90)) # 90°

elif label == "BLUE": # Blue bin

servo.duty(angle_to_duty(180)) # 180°

else: # Unknown bin

servo.duty(angle_to_duty(45)) # Middle fallback

print("SORT:MOVE", label) # Print move

time.sleep(0.5) # Wait to settle

# ===== Main loop =====

print("RUN:Color Detector") # Announce start

while True: # Continuous operation

r, g, b = sample_rgb() # Probe channels

label, conf = classify_rgb(r, g, b) # Classify color

react_by_color(label, conf) # Optional color‑coded behavior

sort_by_color(label) # Move servo to sort

time.sleep(0.2) # Small pacing delay

External explanation

- What it teaches: How to turn a single analog sensor into a “color detector” by illuminating with R/G/B and reading reflectance, then mapping labels to robot actions and sorting with a servo.

- Why it works: Different colors reflect colored light differently; collecting three brightness samples gives a simple fingerprint; thresholds and confidence convert it into reliable, explainable decisions.

- Key concept: “Probe → measure → classify → act.”

Story time

You shine red, then green, then blue—three quick pulses. The sensor whispers back numbers, and suddenly “RED” isn’t just a word; it’s a nudge left and a gentle servo swing into the red bin. Small signals, clear decisions, satisfying motion.

Debugging (2)

Debugging 7.1.1 – Does not distinguish similar colors

Problem: Red vs. orange or teal vs. green gets misclassified.

Clues: Margin (CONF) is small; “UNKNOWN” appears often.

Broken code:

thr = 0.01 # Threshold too low; accepts weak dominance

Fixed code:

thr = 0.05 # Raise dominance threshold for cleaner labels

print("DEBUG:THR", thr) # Verify threshold

Why it works: A higher margin requirement avoids fragile decisions on near‑similar colors.

Avoid next time: Average multiple samples and subtract ambient to sharpen differences.

Debugging 7.1.2 – Lighting conditions affect detection

Problem: Room lights or shadows change readings.

Clues: Ambient (LEDs OFF) is high or variable; RGB:VAL swings widely.

Broken code:

# No ambient subtraction used

val = read_gray()

Fixed code:

amb = read_gray() # Measure ambient with LEDs OFF

val = max(0.0, read_gray() - amb) # Subtract ambient for each channel

print("DEBUG:AMB", round(amb,3)) # Track ambient level

Why it works: Removing ambient makes the readings reflect your LED color rather than the room.

Avoid next time: Shade the sensor area and keep height consistent.

Final checklist

- ADC prints raw and normalized brightness consistently

- RGB probing prints clear channel values for R/G/B

- Classification prints COLOR:CLASS with label and confidence

- Color behaviors nudge motors gently and stop safely on UNKNOWN

- Servo sorting maps labels to 0°/90°/180° positions with printed duty

- Fixes for ambient light and thresholds are ready if conditions change

Extras

- 🧠 Student tip: Make a calibration card: measure R/G/B on white and black to set sane thr and confidence expectations.

- 🧑🏫 Instructor tip: Have teams log 10 samples per color and compute averages; compare the margin across materials.

- 📖 Glossary:

- Reflectance: How much light a surface bounces back under a color channel.

- Dominance (margin): Difference between top and second channel brightness.

- Ambient subtraction: Removing background light from measurements.

- 💡 Mini tips:

- Use consistent resistors for R/G/B so channels are comparable.

- Add a small hood around the sensor to reduce stray light.

- Print short tags only; classroom logs should be easy to scan.